เป็นเครื่องอบแห้งแบบแช่แข็ง (Freeze Dryer) ที่ออกแบบมาเพื่อการแช่แข็งและอบแห้งอาหารอย่างมีประสิทธิภาพ ซึ่งเหมาะสำหรับการใช้งานในเชิงพาณิชย์ ห

รือการผลิตอาหารที่ต้องการความคงทนและคุณภาพสูง

- กระบวนการทำงาน: ใช้การแช่แข็งอาหารให้ถึงอุณหภูมิที่ต่ำสุดและการระเหิดน้ำออกจากอาหารโดยไม่ทำให้โครงสร้างอาหารเสียหาย การใช้เทคโนโลยีนี้ช่วยรักษาคุณค่าทางโภชนาการของอาหารได้ดีกว่า

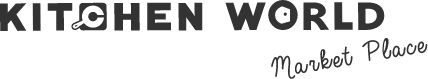

- วัสดุ: ผลิตจากสแตนเลสสตีลคุณภาพสูง ทนทานและง่ายต่อการทำความสะอาด

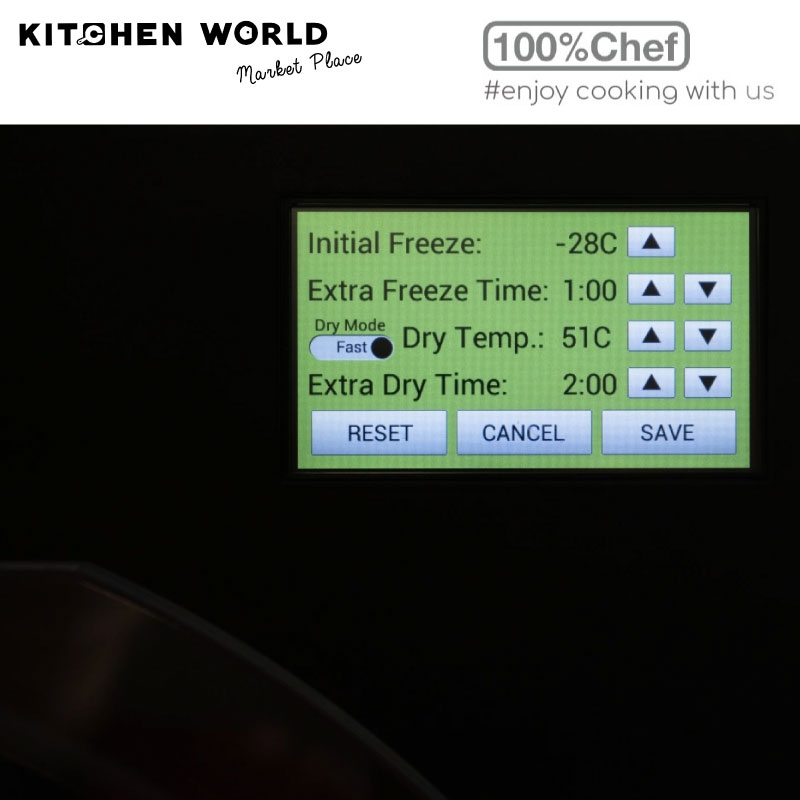

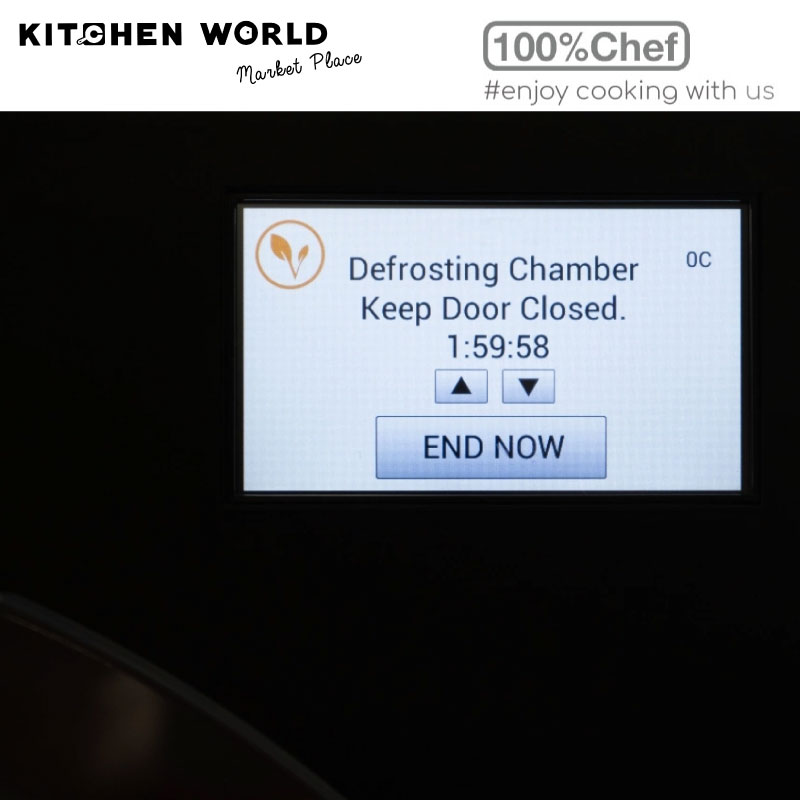

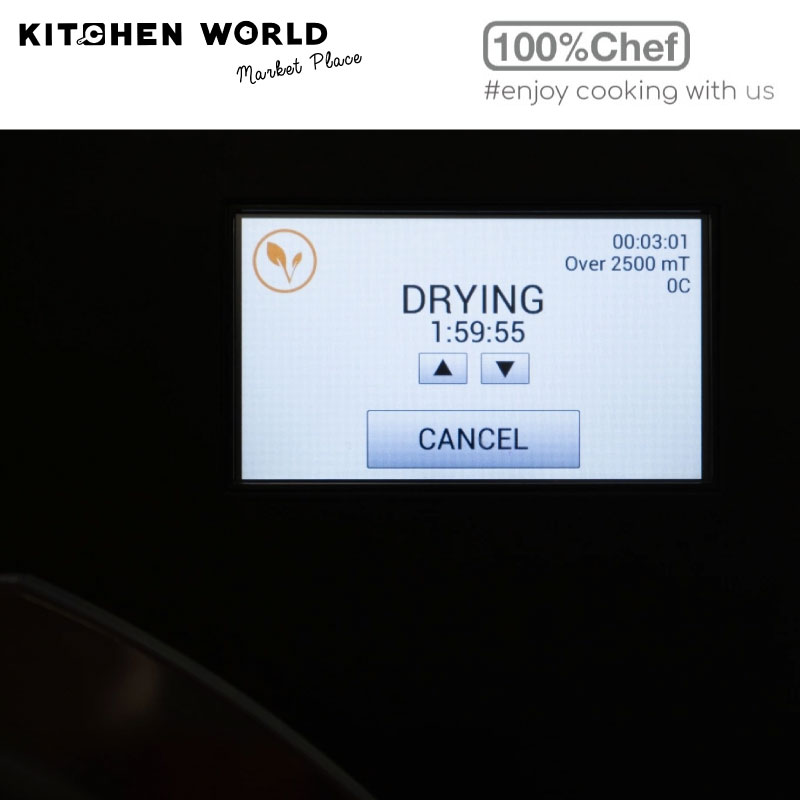

- การควบคุม: ควบคุมการทำงานผ่านระบบดิจิตอลที่ช่วยให้ตั้งค่าพารามิเตอร์ต่างๆ ได้ง่ายและแม่นยำ

- เหมาะสำหรับ: การแช่แข็งและอบแห้งอาหารที่มีความละเอียดสูง เช่น ผลไม้, ผัก, เนื้อสัตว์, สมุนไพร, หรือแม้กระทั่งอาหารสำหรับการฉุกเฉินหรือการเก็บรักษาอาหารในระยะยาว

ฟังก์ชันการใช้งาน:

- การแช่แข็งและอบแห้ง: สามารถแช่แข็งและอบแห้งอาหารในปริมาณมากโดยไม่ทำให้สูญเสียสารอาหารสำคัญ

- การเก็บรักษาอาหาร: เครื่องนี้ช่วยเก็บรักษาคุณภาพของอาหารได้เป็นเวลานาน โดยที่ยังคงรสชาติและสารอาหารไว้

- เหมาะกับการใช้งานเชิงพาณิชย์: เหมาะสำหรับการใช้งานในธุรกิจอาหาร, โรงงานผลิตอาหาร, หรือการเตรียมอาหารสำหรับการใช้งานในระยะยาว

DESCRIPTION

This integrated freeze-drying system reduces the space it takes up in your bakery and makes it as easy as possible to control the entire process. It is an equipment designed for the real needs of caterers and at an unbeatable price.

The Lyo Chef gastronomic freeze dryers have been designed for freeze drying small batches of products. Its compact design and powerful features will meet the needs of any Chef, allowing the production in 24 hours of those products that due to their quality or lack of supply on the market are not available.

We have 2 sizes and capacities available:

Lyo Chef L 54 x 70 x 79.5 cm

How Lyo Chef works

Place the fresh food on the trays, close and start the Lyo Chef. The first phase is to freeze the chamber and the food. Its powerful blast chiller pump will bring the chamber down to -50°C, at which point the special high vacuum pump will start up.

You will be able to see the times, temperatures and process status on the LCD display at all times.

The freeze-drying process will then begin. The trays will begin to temper thanks to a thermal silicone that has the support of the trays, this causes the temperature of the food to drop a few degrees. This drop will generate enough evaporation for the product to dry out. The steam released will be trapped on the walls of the main chamber. This process is repeated throughout the process and accelerates the sublimation process.

Once the selected time has elapsed, we pressurize the chamber again and remove the food and store it in vacuum-tight jars or a dry cupboard until it is ready for use. These products can be stored for years if they are preserved from humidity.

Set the defrost position and open the Lyo Chef exhaust valve. The ice layer that has formed around the chamber will thaw completely, do a thorough cleaning, and start again with a new freeze-drying process.

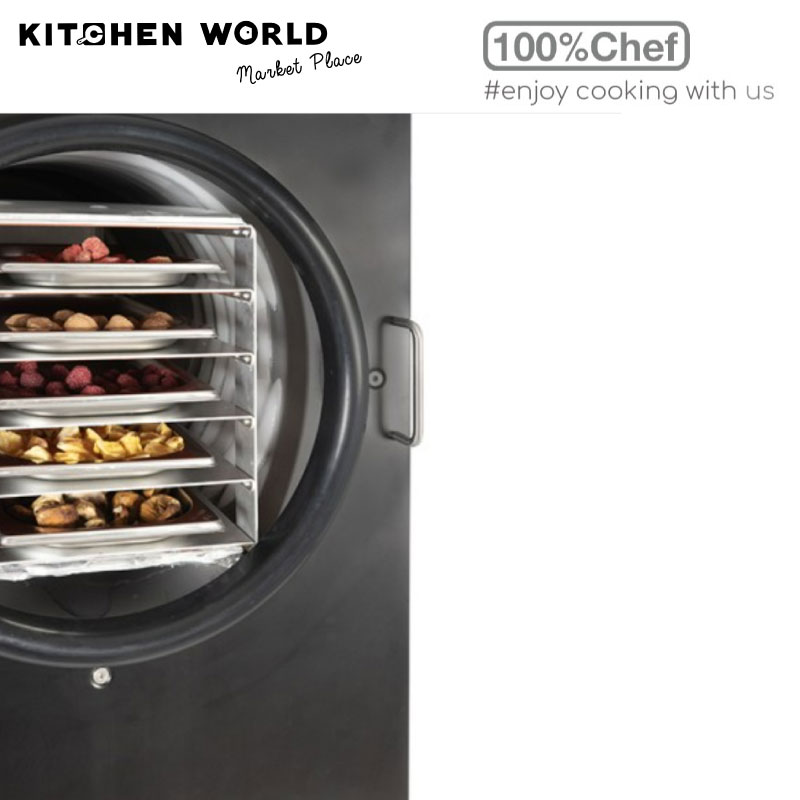

Every three cycles we must drain the oil from the vacuum pump, let it settle and decant any water not trapped by the cold trap, refill the pump again with clean oil and finish filling until the average working level is reached.

We recommend the following products to complete your freeze-drying process:

Lyo Chef M Teflon - 6 pcs: resistant and non-stick sheets on both sides. They do not allow the exchange of flavours between preparations and prevent the products from sticking. They are completely smooth accessories and do not leave marks on the product.

Spare oil for Lyo Chef: in order to carry out good maintenance, Lyo Chef needs to renew the oil in the pump to keep it clean and protect it from corrosion from time to time. This will extend its useful life.

Pump oil filter - 3 pcs: in order to make the most of the pump oil, it is best to use a filter to separate the waste and reuse the oil, thus saving money and helping the environment.

The equipment is complemented by

A high-performance high vacuum pump with synthetic oil to facilitate separation and decanting.

Connections to the freeze-dryer for vacuuming.

Decanting jug.

Pack of bags with sealing bar.

Electric sealing machine with 30 cm bar.

Pack of oxygen absorbing sachets.

TECHNICAL INFORMATION

- Freeze-dry up to 7 kilos per cycle (1,100 kilos of fresh food in one year).

- Actual overall dimensions: 54 wide x 70 deep x 79.5 cm high. 63 kilos.

- Perfect for countertop, trolley or tabletop.

- 6 trays 23 x 52 cm with a total of 0.714 m².

- 220-240V~50/60Hz

The equipment is complemented with a high performance vacuum pump with synthetic oil to facilitate separation and decanting, connections to the freeze dryer to be able to perform the vacuum, decanter jug. Pack of bags with sealing bar, electric sealing machine with 30 cm sealing bar. Pack of oxygen absorbing bags.

Ref.: 70/0049 - Dimensions: 54 x 70 x 79.5 cm

1 year product warranty, excluding consumables and misuse.